Inkdustry GmbH

|

|

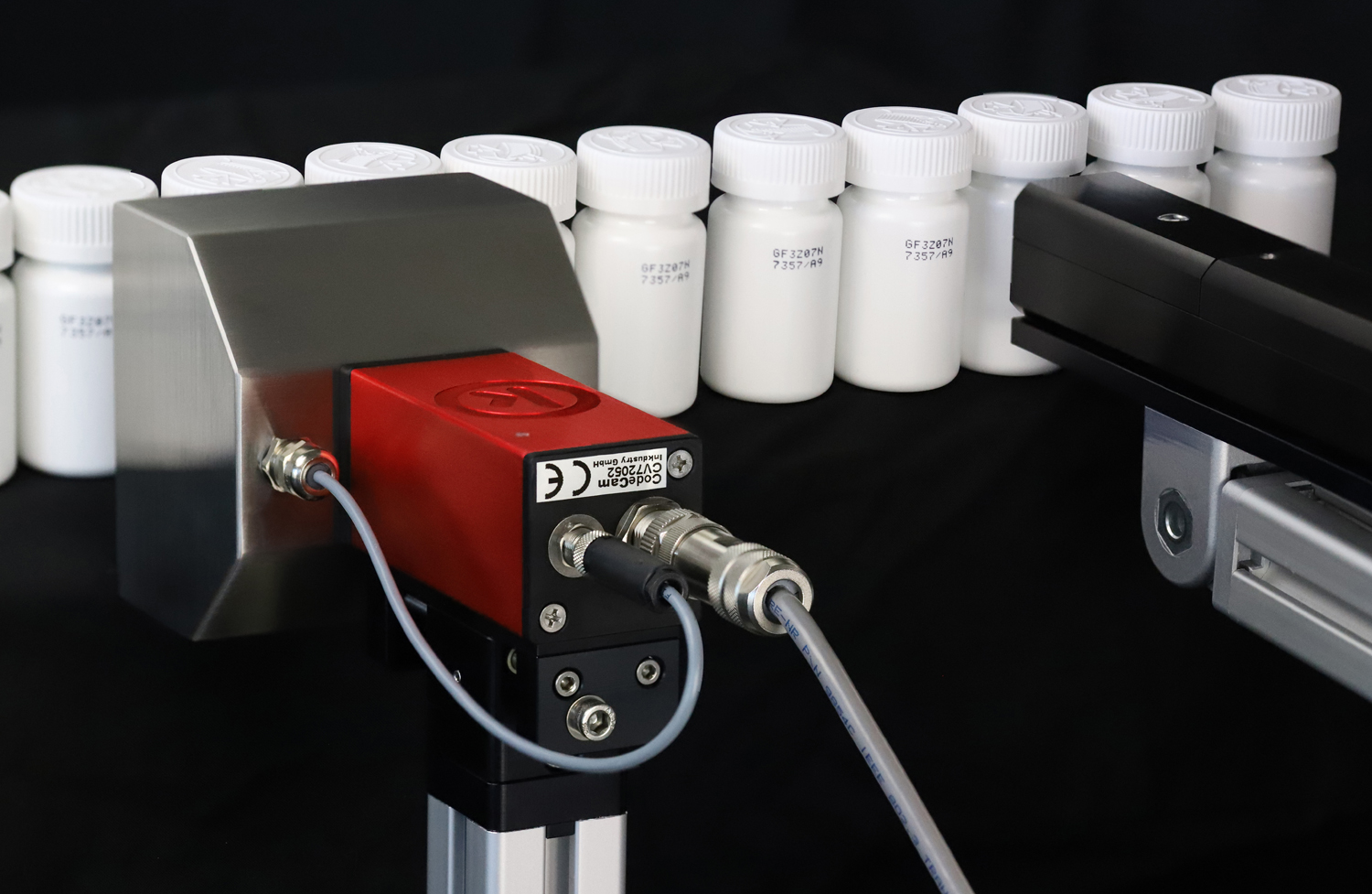

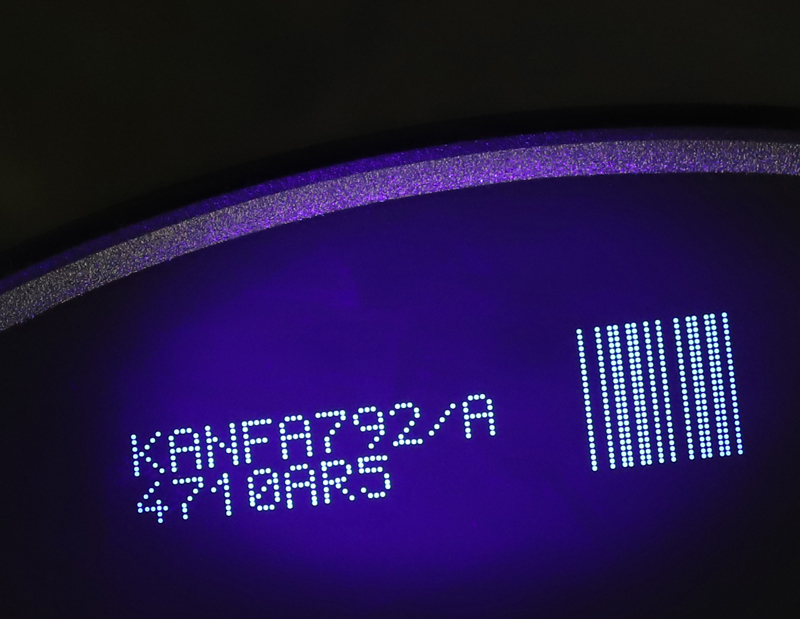

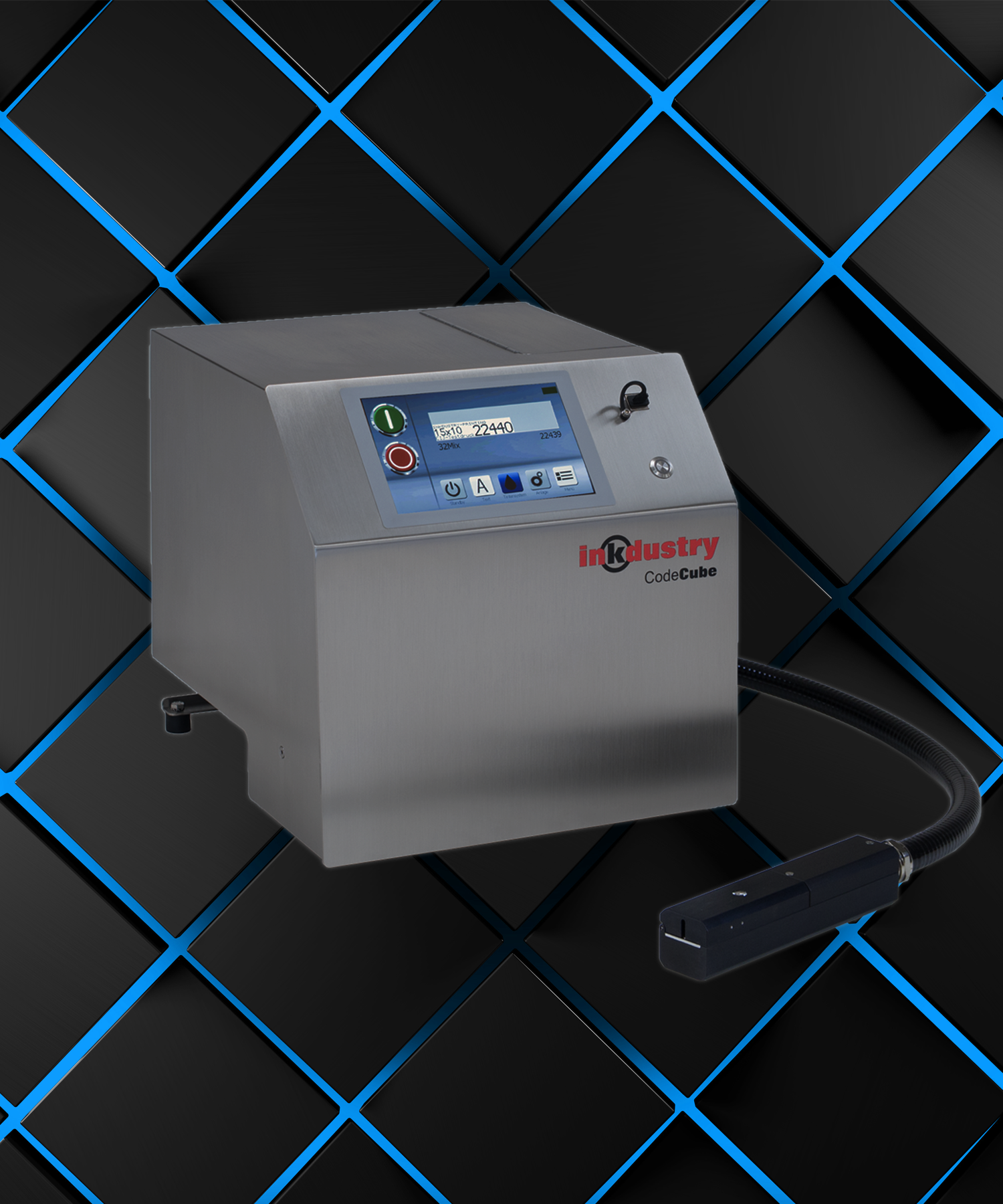

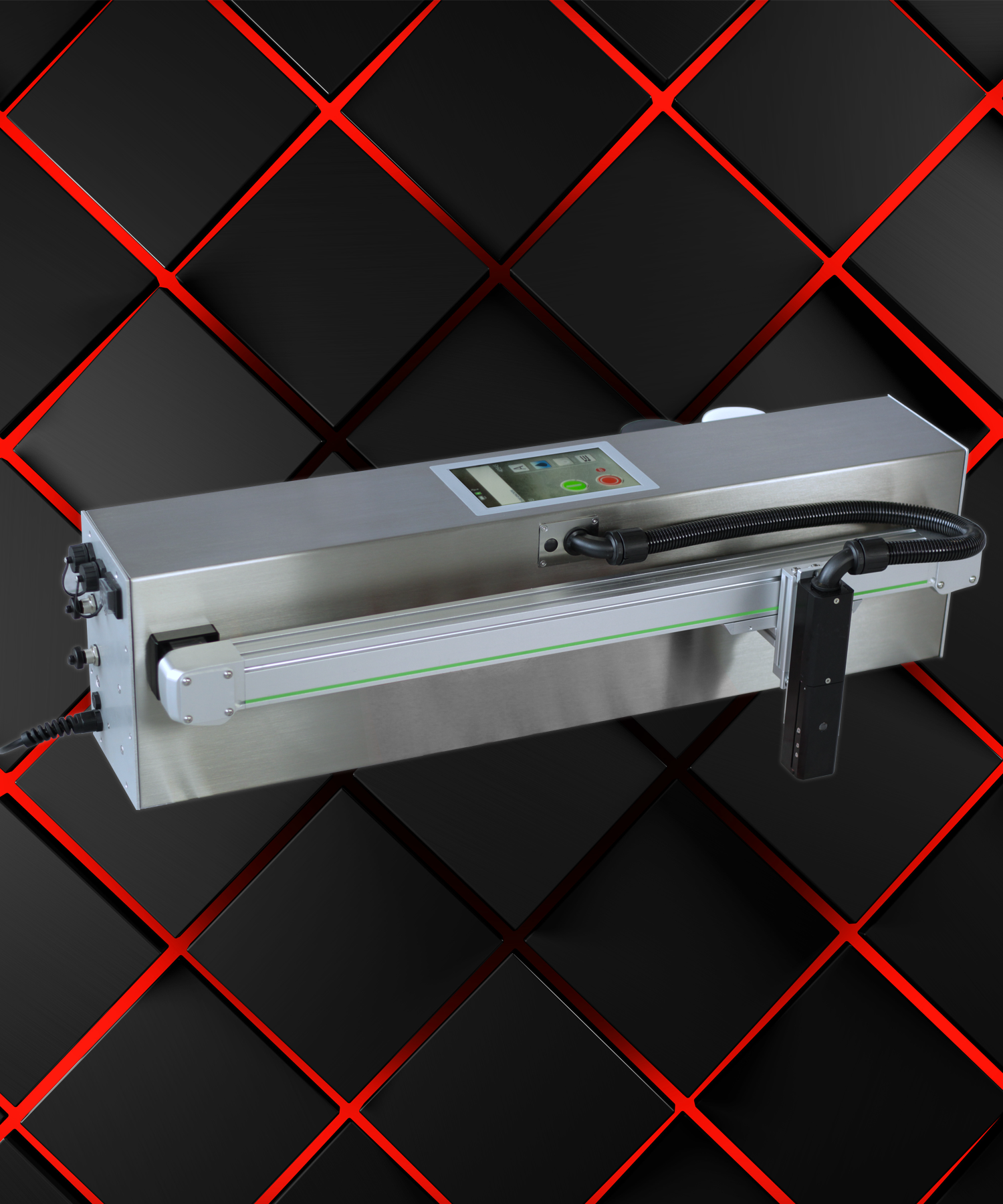

What we do:We are manufacturers of continuous inkjet printers (mostly called CIJ). These are devices that apply tiny drops forming letters and numbers on packagings, bottles, tubes, etc. using fast-drying inks. Our system range starts with the CodeRevo, a standard coding machine for simple applications, convincing with an affordable price. The CodeCubeXL is our universal printer for most regular applications, beside other features, can work with special scripts and various print modes. If special inks, i.e. special colors, bonding, contrasts etc. are required, then the CodeCenter-C is suitable. This high-end all-rounder has, among other things, a solvent recovery, which enormously reduces consumption and emissions and is available with an option for pigmented bright colors. We also provide a solution for 2 headed system, the CodeCenter 2. If two print heads are not enough, the CodeCenter M multi-head system can be used, which combines up to 8 CodeCenter 2 (16 print heads) to a single device. In addition to the application of print texts, it is also important to check that the text is correctly applied to all products. For this reason we have developed the CodeCam, which we have seamlessly integrated into our system series. It creates a complete system from a single source, no external computer is required, and there is no need to teach in the font, which makes handling very easy. |

Who we are:We are the Inkdustry GmbH, a team of specialists in the inkjet sector, from Tauberbischofsheim in Baden-Württemberg. Our core competence extends far beyond the general standard. We place particular emphasis on in-house developments and a high level of vertical production depth. For this reason, we have CNC machining centers, SMD pick and place machines, etc.. The production staff is working with computers at every production place which are running an in-house ERP system. All parts are tagged with barcodes and precisely recorded during all assembly steps, building a complete track and trace system. The software team is constantly working on innovations like the CodeManager software, which acts as a central text and control center, connecting all devices in the in-house network at a central point. |

|